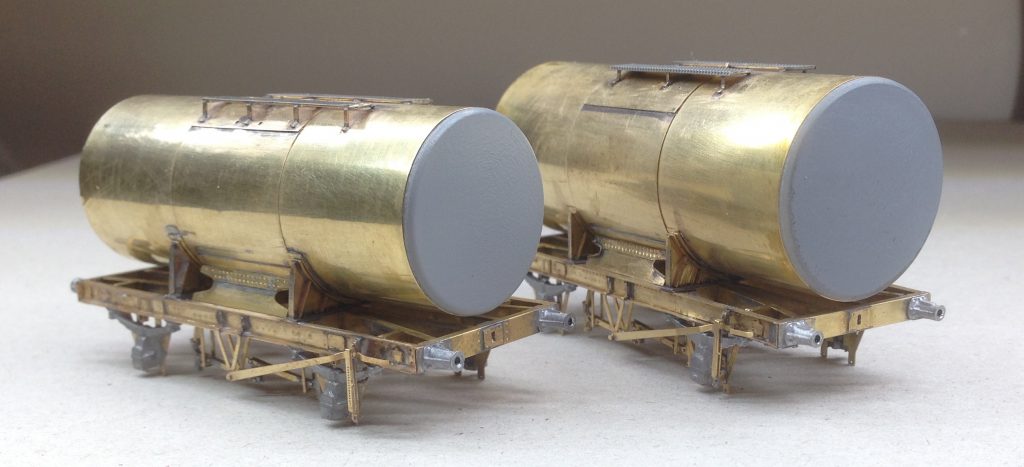

Earlier this year I was asked to produce my anchor mount tank wagon underframes in 7mm scale. Drawing work on these are now complete. In addition I have completed drawing work on etched body parts to go with the underframes for both 7’3” and 6’7” diameter tank wagons. The kits are principally for fuel oil tanks though the underframes could be used for other types such as bitumen tanks. As the bitumen types were insulated and had different anchor mountings they would need different bodies and fittings which I am not considering doing at this time.

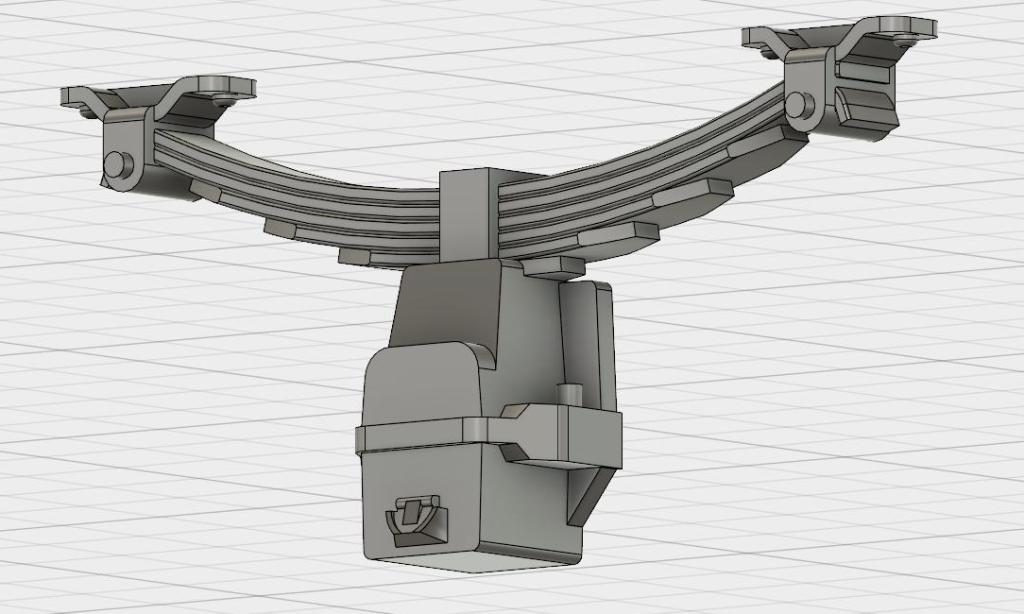

Underframes

These follow the same basic design as my 4mm version and are sprung using guitar wire leaf springs. The chassis is a fold up sandwich type affair with spacers between. They will be etched on 0.4mm brass. There are two kits:

- OB.71 14T underframe with BR type axleguards – click to view pdf

- OB.74 20T underframe with RCH heavy duty type axleguards – click to view pdf

This covers the vast majority of fuel oil tanks built with anchor mountings.

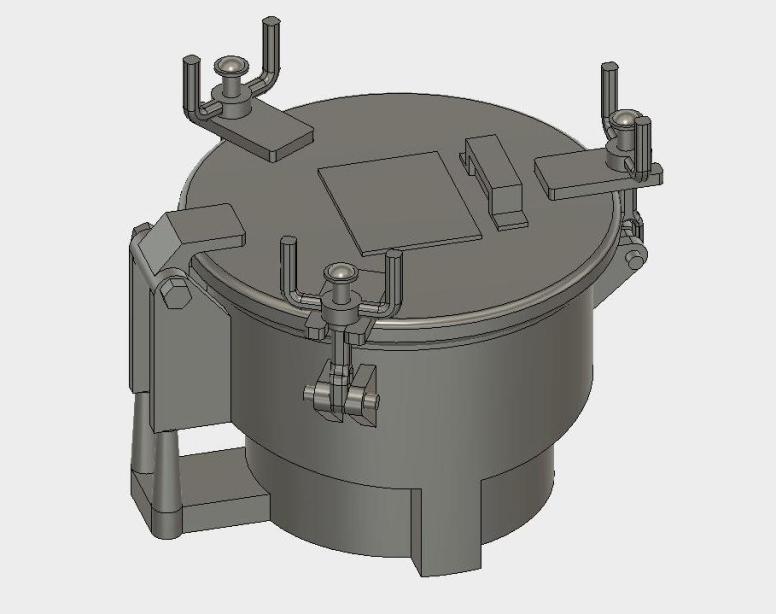

Tank Bodies Parts

These include everything to build the bodies, except for the tank wrappers which can easily be made from 0.010” sheet. This can be summarised as the saddles and anchors, tank formers, Class B drain valve parts, ladders and walkways. Again they will be etched in 0.4mm brass apart from the mesh or chequer plate used on the walkways which will be etched in 0.010” brass. I will do dimensioned drawings for the wrappers in the instructions. There are two kits:

- OC.71 7’3” tank parts – click to view pdf

- OC.72 6’7” tank parts – click to view pdf

Combinations

The four kits can be combined to produce most of the fuel oil tanks built from around 1947. These are summarised as follows:

- OB.71 + OC.71 14T Class A Tanks 14T underframe + 7’3” tank

- OB.71 + OC.72 14T Class B Tanks 14T underframe + 6’7” tank

- OB.72 + OC.71 20T Class B Tanks 20T underframe + 7’3” tank

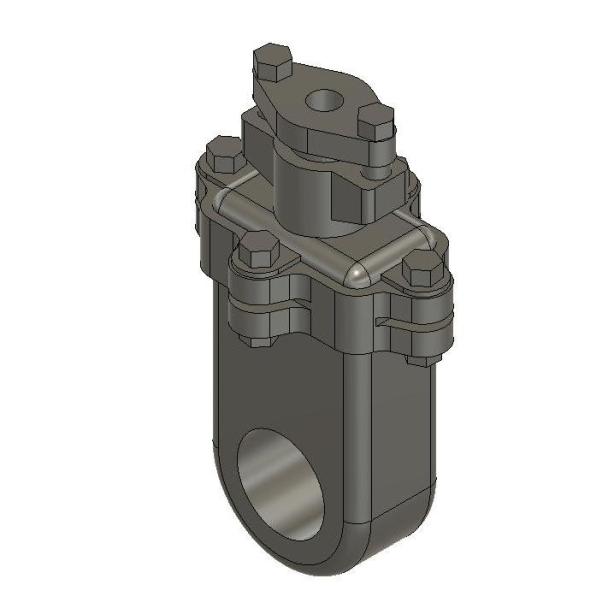

Fittings

As I am doing these wagons in 4mm scale for myself I have been gradually drawing up 3D artwork to go with the etches. So far I have done tanks ends, manholes and the drain valves for class B tanks. There are a few other fittings to be done but once all the artwork for these is complete I will look at producing them in 7mm scale to go with the bodies, this may well be in the form of whitemetal castings from 3D printed masters rather than straight 3D prints. I can also look at doing appropriate springs and axleboxes for the underframes. There is no definitive timescale or price yet for these but if the bodies go ahead then they will be done sooner rather than later.

Prices and Ordering

The underframes are going to be £30 each and the body parts £25 each. In order to go ahead with the etches I’ll need confirmed orders with payment for 15 underframes (in total, there can be a mixture of the two and it doesn’t matter to me if it’s 14 of one and 1 or another) and 15 sets of body etches (again in total with a mix of the two). The underframe and body parts aren’t dependent on each other to go ahead but you must say if you don’t want the underframes without the bodies when ordering. Hopefully this will avoid any issues if there is insufficient demand for the bodies.

My preferred method of payment is by cheque, made payable to “Justin Newitt” not Rumney Models (!) and sent to the address below. These will not be cashed until there are sufficient orders to proceed. If we do not reach the required number I will simply return the cheques. Rather than leaving this open ended I intend to set a deadline of 6th April to order these kits. If we get enough orders to go ahead then I will get the etches done as soon as this happens rather than waiting until April and the parts will then join main Rumney Models 7mm range; if not payments will be returned. Payment can also be arranged by bank transfer (email me for details) but the payee’s bank account details must also be included for returning the money in case of insufficient take up and payments via Paypal (again email me for details) will attract a surcharge; this will be 4% for UK orders and 6% for overseas.

This arrangement is not ideal but I have already spent a lot of time reworking the 4mm artwork and do not wish to do anything further until such time as I know I’m going to be paid for that time and the further work that needs to be done, i.e. instructions and tank wrapper drawings as well as paying for the tooling and the etches themselves.

Justin Newitt

Rumney Models

3 Warren Terrace

Trellech

Monmouthshire

NP25 4PH

justinnewitt@gmail.com